|

Supplier Relationship Management (SRM) Interventions

Case Example: Lean Process Re-engineering Collaboration with a Soft FM Supplier

Background to the Supplier Relationship Management Intervention

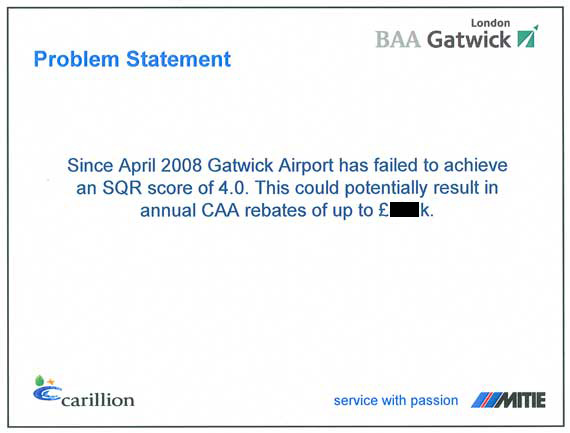

The client was being subjected to substantial contractual payments by the industry regulator, because customer perception of premises cleanliness was failing to meet set standards. In contrast, if the client could achieve the regulator's objectives they would eliminate the contractual payments and be paid an incentivisation payment by the regulator, of up to the same value; a net benefit of double the contractual payments that were being paid out..

The client's incumbent supplier had been replaced earlier that year because a new supplier had proposed a solution involving the introduction of a specialist data collection and management system which would collect the results of facilities inspections from PDAs, to identify patterns of failure. Furthermore the supplier proposed to add substantially more people. This they claimed would deliver the desired result.

After several months it was clear that this wasn't happening, and there was a substantial disconnect between the management style of the client and supplier.

An intensive diagnostic of the level of waste in the existing Soft FM processes confirmed that meeting the minimum standards was possible and that leaner processes would enable the reduction of costs by up to 30% at the same time. This justified the selection of the following supplier relationship management (SRM) intervention approach.

Supplier Relationship Management (SRM) Intervention Approach

- Multi-disciplinary Step Change Task Force Project

It was recognised that a key driver of end customers' perception of facilities cleanliness was the overall condition of the facility itself, which in some parts was fifty years old. Where building fabric is aged, even if it is spotlessly clean, customer perception of cleanliness will be influenced negatively. As such, the team was comprised by a Lean Six Sigma master black belt, provided by the Client and from members of the incumbent Soft FM supplier, and also by a team member from the incumbent Hard FM supplier, whose role was to co-ordinate the selective improvement of building fabric which influenced end customer perception of premises cleanliness.

Objectives of the Multi-disciplinary Step Change Task Force Project

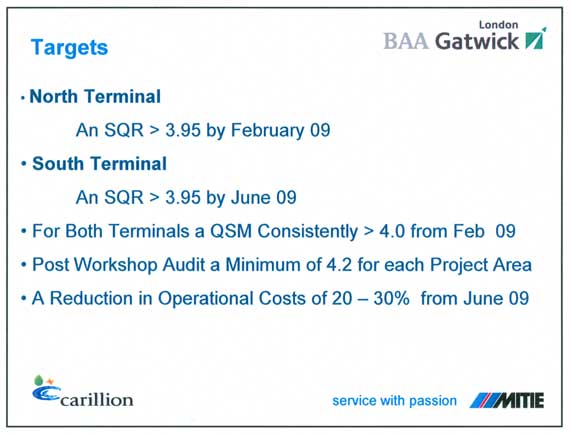

- Improve quality to achieve the regulator's objective.

- Reduce costs by 20-30%

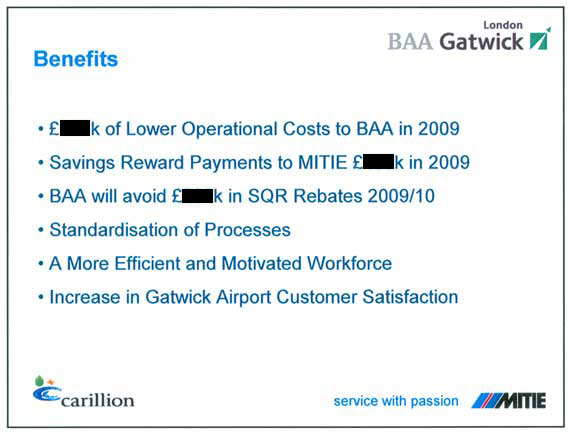

The term "SQR" in the slides below refers to the way in which customer perception of premises cleanliness was reported to the regulator.

Internal Customer

- Premises Facilities Leader

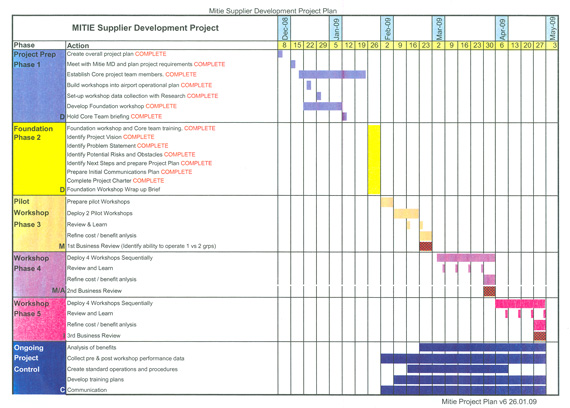

Below are a selection of slides from the multi-disciplinary project team's Launch Presentation.

"Rebates" in the above slide is a reference to the contractual payments to be made by the client to the regulator.

Case Examples of SRM Transformations During Interim Management Assignments

For case examples of SRM transformations which have been delivered, see the following pages:

Driving Supplier Continuous Improvement

Once any substantial step-change performance gaps have been closed scorecards can be used to drive continuous improvement.

More Supplier Relationship Management (SRM) Information

© www .interim-management-purchasing.co.uk December 2012 |

“We would like to take this opportunity to recognize you for making an outstanding contribution to the SHELL Due Dilligence and Integration effort".

"Your involvement has been integral to the success of this undertaking. We recognize the importance of your contribution and greatly appreciate the work you have done"

"Thanks for all the effort re. the Shell integration. You have played a critical role in establishing purchasing in Europe....in many ways a pioneer. Appreciate the dedication".

Excerpt from the European Vice President of Supply Chain's "Applause" award following, the acquisition and integration of four chemicals plants from Shell and the over-delivery of targetted synergies.

NOVA "Applause"

|